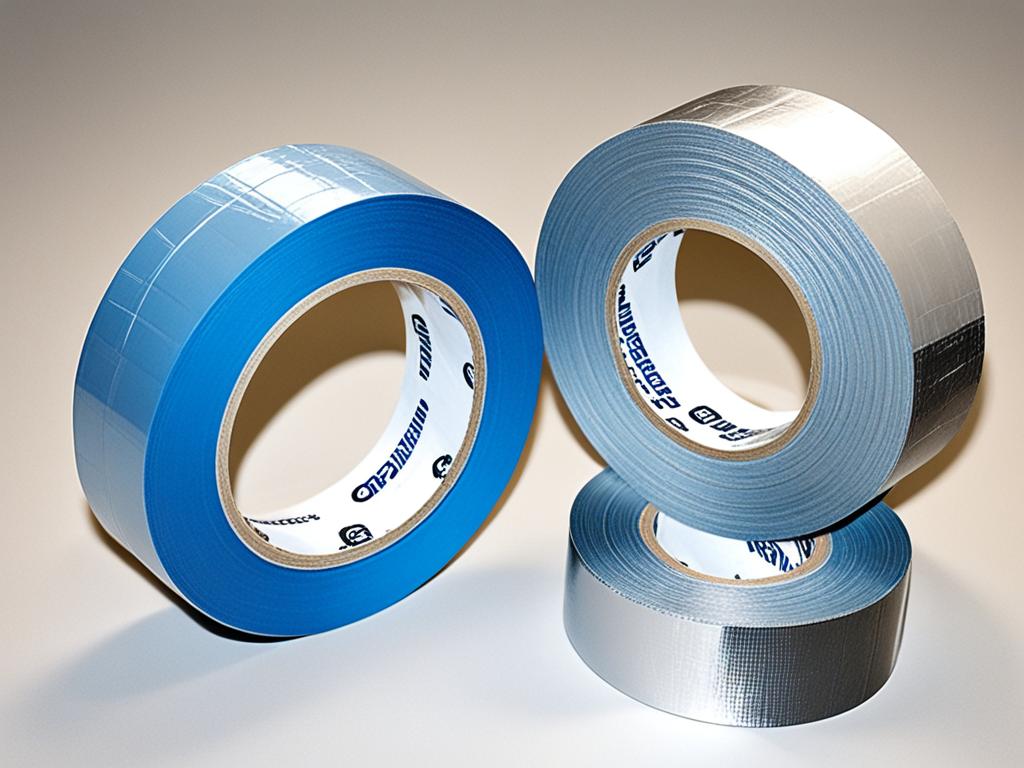

When it comes to choosing the right tape for your next project, understanding the key differences between aluminum tape and duct tape is essential. Each type of tape has its own unique advantages and ideal applications, so using the wrong tape could lead to problems and safety hazards.

Aluminum tape, also known as aluminum foil tape, is a specialized tape commonly used in insulation projects. It is made of aluminum and has a strong adhesive backing, making it ideal for sealing joints and seams in insulation materials. It is also highly resistant to heat and moisture, making it a reliable choice for HVAC systems and other applications where temperature and weather conditions can vary.

Duct tape, on the other hand, is a versatile tape that has a wide range of uses. It is known for its strong adhesive and durable construction, making it suitable for a variety of tasks including temporary repairs, binding objects together, and even crafting projects.

Key Takeaways:

- Aluminum tape, also known as aluminum foil tape, is ideal for insulation projects and HVAC systems.

- Duct tape is versatile and has a wide range of uses, but it should not be used for sealing HVAC ducts.

- Consider the specific requirements of your project, such as temperature resistance and moisture resistance, when choosing between aluminum tape and duct tape.

- If you are unsure which tape to use, consult a professional or ask for help at a home improvement store.

- Using the right tape for the job will help ensure the best results and prevent problems or safety hazards.

Sealing HVAC Ducts: Foil Tape vs. Duct Tape vs. Duct Mastic

When it comes to sealing HVAC ducts, it’s crucial to choose the right tape for the job. There are different options available, each with its own advantages and ideal applications. Let’s compare foil tape, duct tape, and duct mastic to help you make an informed decision.

Foil Tape

Designed specifically for HVAC applications, foil tape offers several benefits that make it ideal for sealing ducts. Here are some key advantages:

- Flame resistance: Foil tape is flame resistant, providing an added layer of safety when used in HVAC systems.

- Durability: It is durable and can withstand high humidity levels without losing its adhesive strength.

- Strong adhesion: Unlike general-purpose duct tape, foil tape maintains its integrity and doesn’t flag or fall off over time, even when affixed to heated insulation materials.

Overall, foil tape is a reliable option that ensures a secure and long-lasting seal, reducing the risk of energy loss and costly heating and cooling bills.

Duct Tape

While duct tape is known for its versatility, it should not be used for sealing HVAC ducts. Duct tape is not designed for HVAC applications and may not provide a reliable and durable seal in the long run. It can degrade over time, leading to energy loss and compromised system performance.

Duct Mastic

Duct mastic is a gooey material that can be applied to seal HVAC ducts. Here’s why it’s worth considering:

- Application versatility: Duct mastic can be easily applied to hard-to-reach areas and sharply angled duct joints using a paintbrush, ensuring a thorough seal.

- Long-lasting seal: It creates a durable and airtight seal that prevents air leaks and energy loss.

When compared to foil tape, duct mastic can be a suitable alternative, especially for challenging duct configurations. It is effective in reducing energy loss and maintaining optimal HVAC system performance.

To summarize, when sealing HVAC ducts, it’s essential to choose tapes specifically designed for HVAC applications. Foil tape and duct mastic are recommended options due to their durability, resistance to moisture and heat, and specialized designs. Remember, using the right tape can help prevent energy loss and ensure efficient heating and cooling in your home or building.

| Tape Type | Advantages |

|---|---|

| Foil Tape | – Flame resistant – Durable in high humidity – Maintains integrity on heated insulation materials |

| Duct Tape | – Versatile, but unsuitable for HVAC duct sealing |

| Duct Mastic | – Can reach inaccessible areas – Creates a long-lasting seal |

Choosing the Right Type of Tape for the Job

When it comes to completing a project successfully, choosing the right type of tape is crucial. Different types of tape are designed for specific applications and offer unique properties to ensure optimal performance and safety.

Electrical tape, also known as insulating tape, is an essential tool for electricians and DIY enthusiasts. Its primary purpose is to insulate electrical wires and provide a protective barrier. Available in various colors, electrical tape enables easy identification and organization of wires.

While duct tape is known for its versatility, it is not recommended for sealing HVAC ducts. For such applications, aluminum foil tape is the preferred choice. With its durability, resistance to moisture and heat, and a specialized design for HVAC systems, aluminum foil tape ensures efficient sealing and prevents energy loss.

For painting projects, masking tape is the go-to option. With its low-grade adhesive, it prevents damage and residue on surfaces, making it easy to achieve clean edges and precise lines.

Securing carpets and area rugs is made easy with carpet tape. Its strong adhesive provides a reliable hold, keeping rugs in place and preventing trips and slips.

When it comes to packaging and shipment, nothing is as reliable as packing tape. With different varieties available based on weight and size requirements, packing tape ensures secure and intact deliveries.

Lastly, for hanging or displaying items without damaging walls, mounting tape is the perfect solution. Its double-sided adhesive properties offer a strong hold, allowing you to decorate and organize with ease.

Remember, choosing the best tape for your specific application is crucial for achieving optimal results. Always opt for high-quality tapes that are designed for the job at hand. So, whether you’re working on electrical projects, sealing HVAC ducts, or completing DIY tasks, having the right tape will make all the difference.

FAQ

What are the main differences between aluminum tape and duct tape?

What are the advantages of using aluminum tape?

Can duct tape be used for sealing HVAC ducts?

What is the best tape for sealing HVAC ducts?

Why is using the right tape for sealing HVAC ducts important?

What are some alternatives to duct tape?

What are the uses of aluminum tape?

What are the advantages of aluminum foil tape?

What properties should be considered when choosing tape for HVAC applications?

Are there specific tapes for different purposes?

How can I choose the right type of tape for my project?

Source Links

- https://www.dydeyou.com/blog/hvac-foil-tape-vs-duct-tape/

- https://murraylampert.com/battle-of-the-tape-duct-mastic-vs-foil-tape/

- https://www.linkedin.com/pulse/hvac-foil-tape-vs-duct-玉东-徐