Choosing the right subfloor plywood is a crucial decision when installing new flooring in your home. It not only provides stability and durability but also impacts the overall insulation of your living space. With different options available, it’s essential to understand the differences and select the plywood that best suits your subflooring needs. In this article, we will compare 5/8 and 3/4 plywood for subflooring and help you make an informed choice.

Key Takeaways:

- Subflooring is an integral part of your flooring structure, providing support, stability, and insulation.

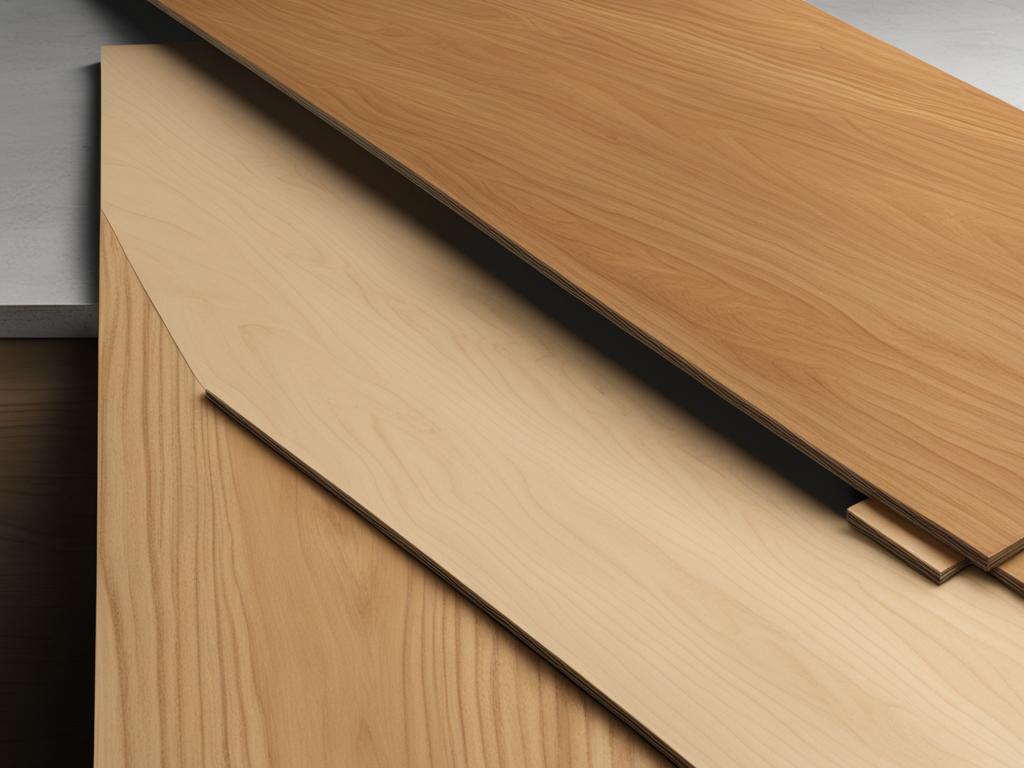

- Plywood, particleboard, and oriented strand board (OSB) are common materials used for subflooring.

- The thickness of the subfloor should consider factors such as joist spacing and vertical spacing.

- 5/8 inch plywood is suitable for subfloors with closer joist spacing, while 3/4 inch plywood is recommended for older homes with wider joist spacing.

- Consider the strength, weight support, insulation, and durability when choosing between 5/8 and 3/4 plywood for your subfloor.

Subfloor Basics: Understanding the Layers

To fully understand the importance of subfloor thickness, it’s essential to grasp the basics of subflooring. A typical flooring structure consists of multiple layers, each playing a crucial role in maintaining the integrity and longevity of the floor.

The first layer is the visible floor covering, which could be carpet, hardwood, vinyl, or tile. This layer not only lends beauty and aesthetics to the floor but also serves as a protective barrier against daily wear and tear.

Beneath the floor covering lies the underlayment, a vital component that provides additional cushioning, sound insulation, and moisture protection. The underlayment acts as a buffer between the floor covering and the subfloor, ensuring a comfortable and quiet experience underfoot.

Now, let’s dive into the subflooring itself. The subfloor serves as the foundation for the entire flooring structure, providing stability, support, and protection against moisture and damage.

Subflooring materials can vary, with the most common options being plywood, particleboard, and oriented strand board (OSB). These materials are chosen for their strength, durability, and resistance to moisture.

The subfloor is like the backbone of your flooring. It’s responsible for ensuring that your floors stay level, sturdy, and protected from subfloor damage.

Without a solid and correctly installed subfloor, your floors may develop squeaks, become uneven, or suffer from moisture-related issues. Subflooring provides the necessary structural integrity for a long-lasting flooring system.

Understanding the different layers of the subflooring system emphasizes the importance of selecting the right subfloor thickness. It’s a critical decision that affects not only the stability and durability of your floors but also the overall comfort and performance of your home.

Factors Affecting Subfloor Thickness

When it comes to determining the optimal thickness of the subfloor, several factors come into play. These factors include:

- Joist Spacing: The spacing of the joists is a significant factor in determining the thickness of the subfloor. Wider joist spacing requires thicker subflooring to ensure stability and prevent sagging.

- Vertical Spacing: The vertical spacing between the subfloor and the crawlspace or slab can impact the insulation and R-value of the flooring system. Proper insulation is essential for energy efficiency and maintaining a comfortable indoor environment.

- Underlayment Options: The choice of underlayment can influence the overall thickness of the subfloor. Some underlayment products offer higher R-values, allowing for thinner subflooring while still providing adequate insulation.

- Subfloor Insulation: Insulating the subfloor is crucial for energy efficiency and noise reduction. The type of insulation used and its R-value contribute to the overall thickness of the subfloor.

- Subflooring Structure: The type of subflooring, whether plywood, particleboard, or OSB, can impact the recommended thickness. Each material has different structural properties and requirements.

Considering these factors is essential to ensure the structural stability and appropriate insulation of your subflooring. By carefully evaluating factors like joist spacing, vertical spacing, and underlayment options, you can make informed decisions that result in a well-built and energy-efficient subfloor.

| Factor | Description |

|---|---|

| Joist Spacing | Wider joist spacing requires thicker subflooring for stability. |

| Vertical Spacing | The vertical space between the subfloor and the crawlspace or slab affects insulation and R-value. |

| Underlayment Options | Choosing underlayment with higher R-values can allow for thinner subflooring. |

| Subfloor Insulation | The insulation type and R-value impact the overall thickness of the subfloor. |

| Subflooring Structure | Different subflooring materials have varying structural requirements. |

Understanding these factors will help you make informed decisions regarding the thickness of your subflooring, ensuring a solid, insulated, and durable foundation for your flooring.

Comparison: 5/8 vs 3/4 Plywood

When it comes to selecting plywood for subflooring, choosing the right thickness is essential. In this section, we will compare the two popular options: 5/8 plywood and 3/4 plywood. Both options have their advantages and considerations, so let’s explore them.

Strength and Weight Support

One of the primary factors to consider is the strength and weight support provided by the plywood. In this aspect, 3/4 plywood takes the lead due to its increased thickness and sturdy construction. The additional thickness provides greater structural integrity and ensures better weight distribution, making it an ideal choice for heavy loads. However, 5/8 plywood can still provide sufficient strength for most subflooring applications, especially in residential settings.

Insulation Capabilities

Insulation is another crucial aspect to consider when choosing plywood for subflooring. Here, 3/4 plywood offers better insulation compared to 5/8 plywood. The increased thickness of 3/4 plywood provides an additional barrier against heat transfer, helping to improve the energy efficiency of your home. However, if insulation is not a primary concern or if you plan on using additional insulation materials, 5/8 plywood can still be a viable option.

Durability and Longevity

When it comes to long-term durability, both 5/8 and 3/4 plywood can deliver reliable results. However, the thicker 3/4 plywood generally offers better resistance to wear, moisture, and other potential damages. It provides a more robust foundation for your flooring, minimizing the risk of sagging, warping, or other structural issues over time. Nonetheless, 5/8 plywood can still provide satisfactory durability, depending on the specific demands of your project.

Ultimately, the choice between 5/8 and 3/4 plywood for subflooring depends on various factors, including your budget, specific structural requirements, and insulation needs. If you prioritize maximum strength, superior weight support, and improved insulation, 3/4 plywood is likely the better option. However, if your project allows for a slightly thinner subfloor without compromising on stability, 5/8 plywood can be a cost-effective choice.

Remember to consult with professionals and consider the specific needs of your project before making a final decision. Choosing the right plywood thickness will ensure a sturdy and reliable subfloor that supports your flooring for years to come.

Conclusion

In conclusion, selecting the right subfloor thickness is crucial for the durability, stability, and insulation of your flooring.

Factors such as joist spacing and vertical spacing impact the optimal thickness of the subfloor. While 5/8 plywood is generally sufficient for subfloors with closer joist spacing, older homes with wider joist spacing may require 3/4 plywood or thicker OSB for stability.

The choice between 5/8 and 3/4 plywood ultimately depends on the specific structural requirements and budget considerations. By understanding the basics of subflooring and considering the factors that affect subfloor thickness, you can make an informed decision and ensure the long-term success of your flooring installation.

Don’t forget to consult with professionals to guide you through the selection and installation process for the best results.

FAQ

Is 5/8 plywood or 3/4 plywood better for subflooring?

The choice between 5/8 plywood and 3/4 plywood for subflooring depends on the specific structural requirements and budget considerations. While both options can be suitable, 3/4 plywood provides greater strength, better weight support, and improved insulation compared to 5/8 plywood.

What is the purpose of the subfloor in a flooring structure?

The subfloor serves as the foundation of the entire flooring structure. It provides structural support, prevents air and moisture penetration, and protects the floor from damage. A sturdy and properly installed subfloor ensures stable and durable flooring.

How do joist spacing and vertical spacing affect subfloor thickness?

Wider joist spacing requires thicker subflooring for stability. The vertical spacing between the subfloor and the crawlspace or slab influences the insulation and R-value of the flooring system. Plywood and OSB offer different insulation properties, so factors like underlayment options should be considered for appropriate insulation.

What are the factors that affect subfloor thickness?

Factors affecting subfloor thickness include joist spacing, vertical spacing, insulation needs, and underlayment options. Joist spacing determines the stability of the subfloor, while vertical spacing impacts insulation. Choosing the right thickness ensures proper structural integrity and insulation for your flooring needs.

How do I choose the best plywood for subflooring?

The best plywood for subflooring depends on factors like joist spacing, weight support needs, and insulation requirements. Generally, 3/4 plywood is recommended for stability and insulation in older homes with wider joist spacing, while 5/8 plywood can be sufficient for subfloors with closer joist spacing. Consult with professionals to make the best choice based on your specific needs.