When it comes to connecting air hoses with tools, inflators, and blow guns, quick-connect couplers called air fittings play a crucial role. However, not all air fittings are created equal. There are significant differences between industrial and automotive air fittings that make them suitable for specific applications. Understanding these differences is essential in order to choose the right type of air fitting for your needs.

Key Takeaways:

- Industrial and automotive air fittings serve the same purpose but have key differences.

- Industrial air fittings are characterized by two stripes, while automotive air fittings have only one stripe.

- The style and size of air fittings are important considerations when choosing the right fit.

- Quick disconnect couplers offer advantages such as secure connections, less kinking, and automatic shutoff valves.

- Identifying the connector style is crucial to ensure compatibility and avoid purchasing the wrong type of air fitting.

Types of Air Fittings

When it comes to air fittings, there are two main types: industrial and automotive. Each type has its own unique characteristics and uses. Let’s take a closer look at these two types and how they differ.

Industrial Air Fittings

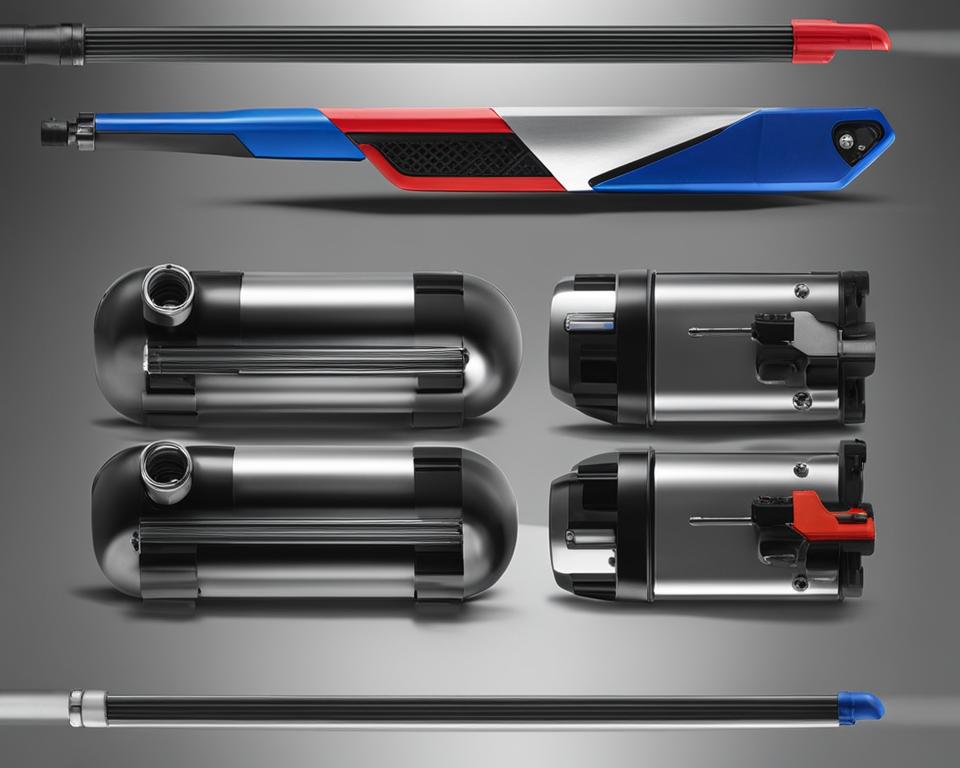

Industrial air fittings are easily identifiable by the two stripes that run across the fitting. These fittings are commonly used in industrial settings and are known for their durability and reliability. The male plug of an industrial air fitting has a beveled outward tip, which helps ensure a secure connection. These fittings are designed to withstand high-pressure applications and heavy-duty use.

Automotive Air Fittings

On the other hand, automotive air fittings have just one stripe and are often used in automotive applications. The male plug of an automotive air fitting has a beveled inward tip, resembling a spark plug. These fittings are designed to be compact and easy to use in tight spaces. They are commonly used in automotive repair shops and garages.

It’s important to note that industrial and automotive air fittings are not compatible with each other due to their differences in design and functionality.

Now that we’ve explored the types of air fittings, let’s move on to the next section to learn more about how to choose the right air fittings for your specific needs.

Choosing the Right Air Fittings

When it comes to selecting air fittings, there are a few important factors to consider. One of the key considerations is the style of air fitting that best suits your needs. The style of the air fitting should align with your personal preferences and the compatibility with your existing fittings. If you already have air fittings in place, it is crucial to purchase the same style to ensure a seamless connection and avoid any compatibility issues. This is particularly important when choosing air fittings for industrial use or automotive use.

For industrial applications, it is common for contractors to use different color air hoses and fittings for each crew. This practice helps in avoiding mix-ups and ensures efficient workflow. By assigning specific color-coded air fittings to each crew, you can easily identify and differentiate the tools or equipment used by different teams.

| Type of Use | Recommended Air Fittings |

|---|---|

| Industrial | Industrial-style air fittings with color-coded hoses |

| Automotive | Automotive-style air fittings |

Choosing the right air fittings for your specific application plays a crucial role in ensuring a secure and efficient air connection. By considering the style and size of the fittings, you can make an informed decision that meets your requirements. Whether you need air fittings for industrial use or automotive use, taking the time to choose the right fittings will result in reliable and consistent performance.

Advantages of Quick Disconnect Couplers

Quick disconnect couplers offer numerous advantages when it comes to joining air hoses with tools and equipment. These couplers are specifically designed to provide a secure and efficient connection, making them an essential component in various industries.

Secure and Reliable Connection

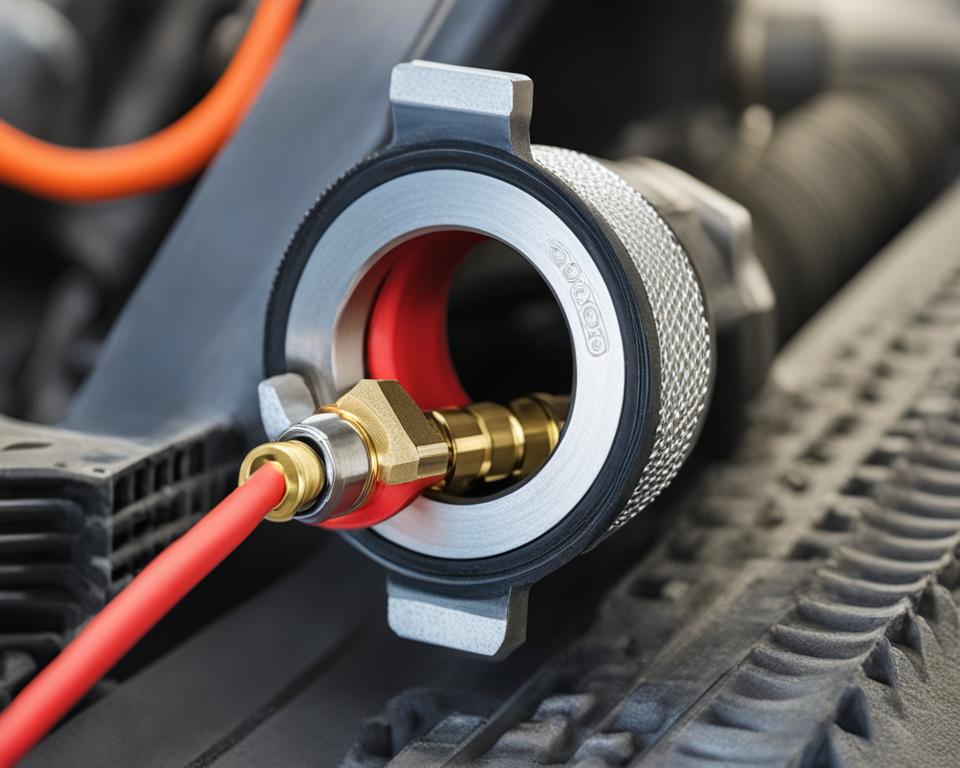

One of the key advantages of quick disconnect couplers is their ability to provide a secure and reliable connection. They feature hardened balls or pins that fit into a slot in the coupler plug, ensuring a tight and stable connection. This eliminates the risk of leaks or disconnections during operation, enhancing safety and productivity in the workplace.

Swivel Feature for Reduced Kinking and Twisting

The swivel feature is another notable advantage of quick disconnect couplers. This design allows the coupler to rotate freely, minimizing kinking and twisting of the hose. By reducing strain on the hose, it extends its lifespan and ensures optimal airflow, resulting in improved performance of pneumatic tools and equipment.

Easy to Insert and Remove

Quick disconnect couplers are designed with a sliding sleeve mechanism that simplifies the process of inserting and removing the plug. When retracting the coupler, the sliding sleeve releases the locking balls, allowing for effortless insertion or removal of the plug. This convenient feature saves time and effort, making it easier to switch between different tools or equipment.

Automatic Shutoff Valve

An automatic shutoff valve is incorporated into quick disconnect couplers, which provides an additional advantage. When uncoupling the fitting, the valve instantly seals, eliminating the need for a separate shutoff mechanism. This feature prevents air leakage, ensuring efficient operation and reducing unnecessary air consumption.

In summary, quick disconnect couplers offer several advantages that make them the preferred choice for joining air hoses with tools and equipment. Their secure connection, swivel feature for reduced kinking, easy insertion and removal, and automatic shutoff valve contribute to improved performance and enhanced productivity in various industries.

Identifying Connector Styles

When it comes to air fittings, identifying the connector style is crucial to ensure compatibility and avoid costly mistakes. In this section, we will discuss how to differentiate between industrial style couplers and automotive style couplers.

Industrial style couplers can be easily identified by the presence of two stripes going across the fitting. These stripes serve as a visual indicator of the industrial style. On the other hand, automotive style couplers feature only one stripe. The difference in stripe pattern is a key characteristic that distinguishes these two styles.

In addition to the stripe pattern, another distinguishing feature is the design of the plug. Industrial style couplers typically have a slightly longer plug with a different head compared to the automotive style. This variation in plug design further aids in identifying the connector style.

Some manufacturers go a step further and stamp their couplers with product numbers. These numbers indicate the style, body size, and thread size of the coupler. By referring to these product numbers, it becomes even easier to identify the precise connector style.

By accurately identifying the connector style, you can ensure that you purchase the right type of coupler for your specific needs. Buying the wrong type can result in compatibility issues and inefficiencies in your air tool system.

| Industrial Style Couplers | Automotive Style Couplers |

|---|---|

| Two stripes on the fitting | One stripe on the fitting |

| Slightly longer plug with a different head | Standard plug design |

| Product numbers stamped on couplers | – |

Conclusion

In conclusion, when it comes to industrial and automotive air fittings, there are distinct differences that should not be overlooked. The style and compatibility of these fittings play a crucial role in their respective applications. Industrial air fittings, characterized by two stripes and a beveled outward tip, are commonly used in industrial settings. On the other hand, automotive air fittings, with one stripe and a beveled inward tip, are more suitable for automotive applications.

When choosing between industrial and automotive air fittings, consider your personal preference, compatibility with existing fittings, and the specific requirements of your application. To ensure a secure and reliable connection, it’s essential to select the correct type of air fitting. Choosing the wrong fitting can lead to compatibility issues and potential safety hazards.

By understanding the differences between industrial and automotive air fittings, you can make an informed decision and avoid potential complications. Whether you’re working in an industrial or automotive environment, selecting the right air fitting will ensure efficient and safe operations.

FAQ

What are industrial and automotive air fittings?

Industrial and automotive air fittings are types of quick-connect couplers used to join air hoses with tools, inflators, and blow guns.

What are the differences between industrial and automotive air fittings?

Industrial air fittings have two stripes going across the fitting and a beveled outward tip, while automotive air fittings have one stripe and a beveled inward tip. They are not compatible with each other.

How do I choose the right type of air fitting?

The style and size of the air fitting should be considered. If you already have fittings, purchase the same style to ensure compatibility. For industrial use, using different color air hoses and fittings for each crew can help avoid mix-ups.

What are the advantages of quick disconnect couplers?

Quick disconnect couplers provide a secure and reliable connection with hardened balls or pins, have a swivel feature to reduce hose kinking and twisting, and a sliding sleeve for easy plug insertion and removal. They also have an automatic shutoff valve to seal instantly when uncoupling.

How can I identify the style of an air fitting?

Industrial style couplers have two stripes, while automotive style couplers have one stripe. The plug of industrial style couplers is slightly longer and has a different head compared to the automotive style. Some manufacturers may also stamp product numbers on the couplers to indicate the style, body size, and thread size.