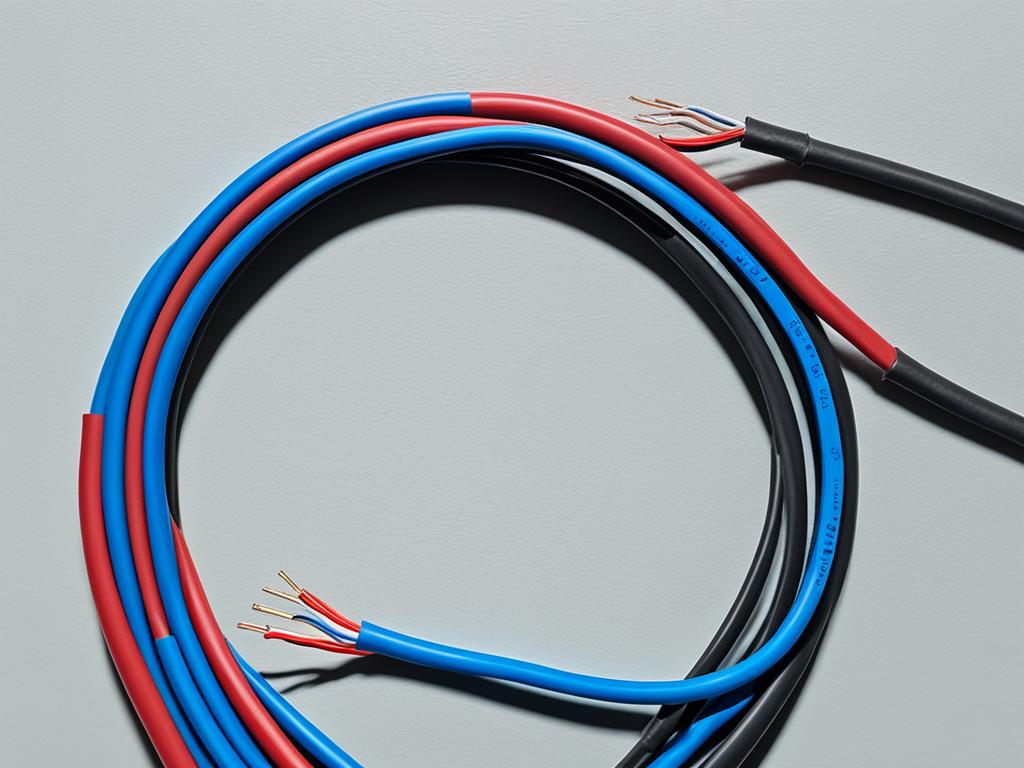

When it comes to electrical wiring, choosing the right gauge is crucial for ensuring safety and efficiency. Two common options you may come across are 6/2 wire and 6/3 wire. Understanding the differences between these wire gauges can help you make an informed decision for your specific needs.

6 gauge wires are widely used in marine, residential, and industrial applications where a medium-sized wire is required. The primary difference between 6/2 and 6/3 wire lies in the number of conductors. While both wires have a gauge size of 6, 6/2 wire consists of two conductors, whereas 6/3 wire consists of three conductors. This difference in conductor count can impact the wiring capabilities and applications of the wire.

Key Takeaways:

- 6 gauge wires are commonly used in marine, residential, and industrial applications.

- The difference between 6/2 and 6/3 wire lies in the number of conductors.

- Understanding wire gauges and specifications is crucial for selecting the appropriate wire for your electrical project.

- Consider the ampacity, diameter, and current capacity of the wire when choosing between 6/2 and 6/3 wire.

- Making an informed decision ensures the successful completion of your wiring project.

Understanding Wire Gauges and Specifications

In the world of electrical wiring, wire gauges play a crucial role. Understanding the specifications and properties of wire gauges is essential for selecting the right wire for your electrical projects. Let’s delve into the details and explore the key factors related to wire gauges.

Wire gauges refer to the thickness of the wire, with smaller gauge numbers indicating thicker wires. The American Wire Gauge (AWG) is the widely accepted standard for measuring wire thickness in the United States. It provides a consistent and reliable method for determining wire size across various applications.

One of the primary considerations when working with wire gauges is the wire diameter. Wire diameter directly correlates with the gauge number, allowing for easy identification of wire thickness. For example, a 16-gauge wire will have a smaller diameter than a 12-gauge wire.

Wire area is another crucial specification determined by the wire gauge. The area of a wire directly affects its current carrying capacity. As the wire gauge increases, the wire’s cross-sectional area decreases, resulting in a decrease in current capacity. Hence, thicker wires with larger areas can carry higher amounts of current without overheating.

Wire resistance is also influenced by wire gauges. Thicker wires have lower resistance, allowing for greater energy efficiency and minimizing voltage drops over longer distances. Understanding the resistance of different wire gauges helps ensure the proper functioning of electrical circuits.

When it comes to selecting the right wire gauge for specific applications, it’s essential to consider the wire’s current capacity. The current carrying capacity of a wire depends on its gauge and the material it is made of. Wire gauge charts provide valuable information to determine the maximum current a wire can carry safely.

To help you visualize the relationship between wire gauges, diameter, area, resistance, and current capacity, take a look at the wire gauge chart below:

Use this chart as a reference when working with wire gauges to ensure you’re selecting the right wire thickness and gauge for your specific electrical applications.

Ampacity and Applications of 6 Gauge Wire

In electrical wiring, ampacity refers to the maximum current that a wire can safely carry without overheating or causing damage. Understanding the ampacity of 6 gauge wire is crucial when determining its suitability for different applications.

For residential use at a maximum temperature of 60°C/140°F, the ampacity of 6 gauge wire is 44 Amps. This makes it suitable for various household circuits, including lighting circuits and outlet circuits. The 6 gauge wire’s current carrying capacity ensures safe and efficient operation for these everyday applications.

However, for heavy-duty applications that require higher current carrying capacity, thicker gauges, such as 4 gauge wire, are more appropriate. These heavier wires are commonly used in applications like furnaces and large heaters, where the electrical load is greater.

When selecting the right wire gauge for your specific wiring needs, it’s important to consider the ampacity requirements of your application. Using wires with inadequate ampacity can lead to overheating, voltage drop, and potential safety hazards. Conversely, using wires with excessive ampacity may be unnecessary and can result in increased costs.

By understanding the ampacity of 6 gauge wire and its applications, you can make informed decisions that ensure the safe and efficient operation of your electrical systems.

| Wire Gauge | Ampacity (60°C/140°F) | Common Applications |

|---|---|---|

| 6 gauge | 44 Amps | Lighting circuits, outlet circuits in homes |

| 4 gauge | 70 Amps | Furnaces, large heaters |

Conclusion

Choosing the right wire gauge is a crucial decision when it comes to electrical wiring projects. Whether you are deciding between 6/2 and 6/3 wire, it’s important to consider the specific requirements of your application. By understanding wire gauges and specifications, you can ensure that you select the appropriate wire for your project.

One key factor to consider is the number of conductors needed. This will help you determine whether 6/2 or 6/3 wire is suitable for your electrical setup. Additionally, it’s essential to take into account the ampacity, diameter, and current capacity of the wire. By ensuring that the wire can safely carry the load, you minimize the risk of electrical hazards and ensure the successful completion of your project.

So when it comes to wire gauge selection, remember to make an informed decision. Evaluate the specific requirements of your application, understand the wire gauges and specifications, and consider factors like ampacity and current capacity. By taking these factors into account, you can confidently choose the right wire gauge for your electrical wiring projects.