When it comes to choosing the right joist for your construction project, there are many options to consider. Two popular choices are TGI joists and TJI joists. In this article, we will explore the differences between these two engineered joists, weighing their strengths, costs, and performance. Whether you’re building a residential or commercial structure, understanding the distinctions between TGI and TJI joists will help you make an informed decision.

Key Takeaways:

- Both TGI and TJI joists are engineered wood joists used in construction projects.

- TGI joists are known for their strength, stability, and resistance to shrinking and warping.

- TJI joists are lightweight and can span further distances, making them more efficient in some cases.

- The choice between TGI and TJI joists depends on factors such as load requirements, span distances, and budget considerations.

- Consulting with a structural engineer or construction professional is recommended to determine the best option for your project.

What Does TJI Joist Stand For?

TJI stands for Truss Joist I-Joist, and it is a trademarked name for engineered wood I-joists. Trus Joist, a Weyerhaeuser business, is the company that invented the engineered wood I-joist and held the patent for it.

TJI joists are designed to resist twisting, shrinkage, and warping, making them a reliable choice for structural support in construction projects. These innovative joists use less wood compared to standard joists, which not only makes them lighter but also more efficient from a resource utilization perspective. The TJI joist technology offers a sustainable and environmentally friendly alternative to traditional wooden joists.

With their exceptional strength and stability, TJI joists provide architects and builders with versatile solutions for creating sturdy and durable structures. Let’s explore the benefits of TJI joists in more detail.

Sustainability and Efficiency

The design of TJI joists allows them to optimize the use of wood resources without compromising structural integrity. By using less wood, TJI joists help conserve forests and reduce environmental impact. They are manufactured using advanced engineering techniques that maximize strength while minimizing material requirements, resulting in a sustainable and efficient product.

Strength and Stability

TJI joists are engineered to provide excellent load-bearing capacity and structural stability. The combination of wood fibers and engineered adhesives gives TJI joists consistent strength and dimensional stability. This ensures that the joists won’t warp or twist over time, providing long-lasting support for floors, ceilings, and roofs.

“TJI joists offer reliable strength and stability, making them a popular choice among architects and builders who prioritize structural integrity in their construction projects.”

Flexibility in Design

Trus Joist offers a wide range of TJI joist sizes and depths to accommodate diverse construction requirements. This flexibility in design enables architects and engineers to create open floor plans, longer spans, and greater design freedom. Whether it’s residential, commercial, or industrial construction, TJI joists provide the versatility needed for different project types.

Now that we understand what TJI joists are and their design principles, let’s explore the various applications where these innovative engineered joists excel.

What Are TJI Joists Used For?

TJI joists, also known as Truss Joist I-Joists, are versatile engineered wood products that find wide applications in construction projects. These innovative joists serve various purposes, including as interior floor joists, trusses, and headers.

One key advantage of using TJI joists as floor joists is their ability to span further than traditional dimensional lumber of similar sizes. This allows for larger open spaces or rooms without the need for additional support columns or walls. TJI floor trusses provide the structural integrity needed to support the weight of the floor and other loads.

Trusses, another common application for TJI joists, are triangular frameworks used to provide support to roofs, floors, and bridges. The strength and reliability of TJI joists make them an ideal choice for constructing trusses, ensuring stability and durability in various structures.

Headers, also known as beams or lintels, play a crucial role in supporting the load above window or door openings. TJI joists can be used as headers due to their high load-carrying capacity and dimensional stability, providing the necessary strength to bear the weight from above.

In addition to their versatility, TJI joists offer other advantages. Their lightweight nature makes them easier to handle and install, reducing labor time and costs. Furthermore, TJI floor joists can be cut or drilled to allow for the passage of essential utilities such as plumbing, electrical, and HVAC systems. This helps to minimize obstructions below the joists and eliminates the need for bulky bulkheads, providing a clean and unobstructed space.

Overall, TJI joists are widely used in residential and commercial construction projects, offering superior strength, flexibility in design, and cost-effectiveness. Their use as floor joists, trusses, and headers contributes to the creation of sturdy and efficient structures.

TJI Joist Sizes

TJI joists come in a range of sizes to accommodate different construction needs. The sizes of TJI joists are determined by their design properties and product numbers. These engineered wood products are manufactured by Trus Joist under their patented TJI brand. Here is an overview of the available TJI joist sizes:

| TJI Joist Size | Width | Depth |

|---|---|---|

| TJI 110 | 1-3/4″ | 9-1/2″ |

| TJI 210 | 1-3/4″ | 11-7/8″ |

| TJI 230 | 1-3/4″ | 14″ |

| TJI 360 | 3-1/2″ | 11-7/8″ |

| TJI 560 | 3-1/2″ | 16″ |

The TJI joist sizes range from TJI 110 with a width of 1-3/4″ and a depth of 9-1/2″ to TJI 560 with a width of 3-1/2″ and a depth of 16″. The specific size of TJI joist required for a project depends on the design requirements and the desired span distance.

When choosing the right TJI joist sizes, it is important to consider the load requirements and the structural demands of the construction project. Consulting with a structural engineer or a construction professional can help ensure that the appropriate TJI joist size is selected to meet the project’s specifications.

How Far Can TJI Floor Joists Span?

The maximum span of TJI floor joists depends on various factors such as spacing between joists, load requirements, deflection ratios, sheathing thickness, and other design factors. It is important to refer to the manufacturer’s specifications, local building codes, or consult a structural engineer to determine the appropriate span for a specific project.

When considering the span of TJI floor joists, it is essential to take into account multiple factors that can affect their performance and structural integrity. The span refers to the distance that the joists can cover without the need for additional support. Here are a few significant factors to consider:

- Spacing between joists: The closer the joists are spaced, the shorter the span distance they can effectively cover. For TJI floor joists, common spacing options include 12 inches, 16 inches, and 24 inches.

- Load requirements: The intended use of the floor, the weight it needs to support, and any additional loads such as furniture, appliances, or occupants must be considered when determining the appropriate span for TJI floor joists.

- Deflection ratios: Deflection refers to the degree of flex or bending that occurs in a joist under load. The appropriate deflection ratio must be maintained to ensure the structural integrity and longevity of the floor system.

- Sheathing thickness: The thickness and type of sheathing material used on top of the floor joists can significantly impact their span capabilities. Thicker and sturdier sheathing materials provide additional support and allow for longer spans.

- Other design factors: Additional design factors, such as the presence of load-bearing walls or beams, can affect the span of TJI floor joists. These factors may require specific engineering considerations and adjustments to determine the appropriate span distance.

Maximum Span for TJI Floor Joists

| TJI Joist Product Number | Spacing | Maximum Span |

|---|---|---|

| TJI 110 | 24″ centers | 13’7″ |

| TJI 210 | 24″ centers | 16’6″ |

| TJI 230 | 24″ centers | 17’6″ |

| TJI 360 | 16″ centers | 22’3″ |

| TJI 560 | 12″ centers | 36’1″ |

These figures serve as a general guide and may vary depending on the specific project requirements and local building codes. It is crucial to consult the manufacturer’s specifications and collaborate with a structural engineer to determine the precise maximum span for TJI floor joists in your construction project.

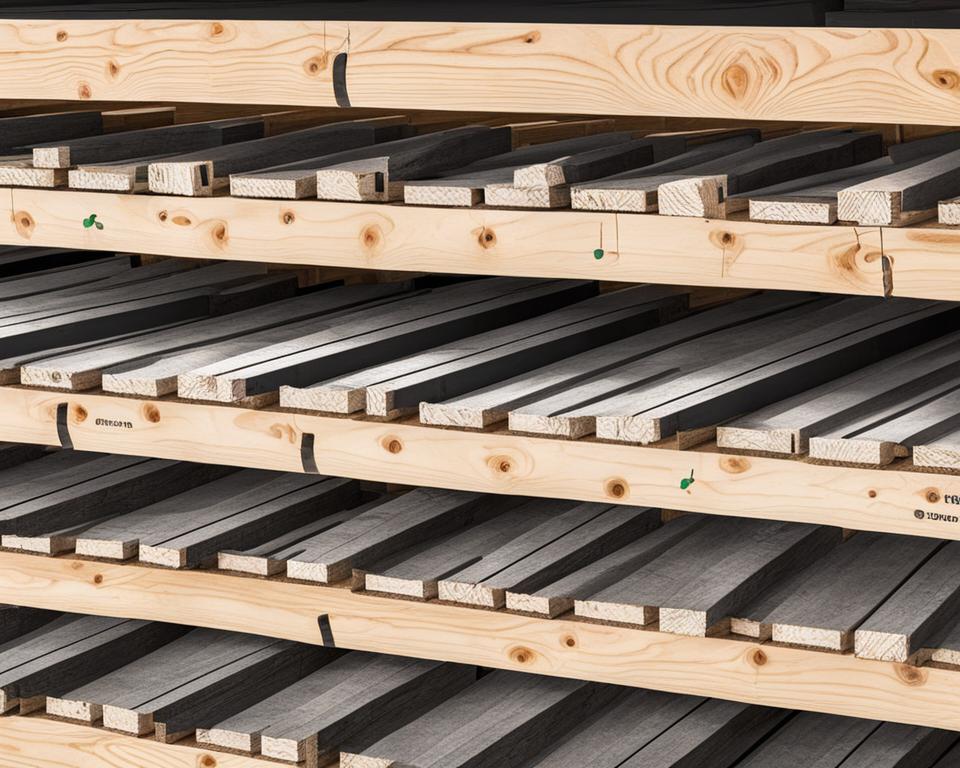

Note: The image above illustrates the span capabilities of TJI floor joists, showcasing their suitability for various construction projects.

TGI vs TJI

When it comes to comparing TGI and TJI joists, both are engineered wood joists that offer several benefits over traditional dimensional lumber. TGI joists are known for their strength, stability, and resistance to shrinking and warping. TJI joists, on the other hand, are lighter in weight and can span further distances. The choice between TGI and TJI joists will depend on factors such as load requirements, span distances, and budget considerations.

| Comparison | TGI Joists | TJI Joists |

|---|---|---|

| Strength | High | High |

| Stability | High | High |

| Resistance to Shrinking and Warping | High | N/A |

| Weight | Heavier | Lighter |

| Span Distance | Shorter | Longer |

Conclusion

In conclusion, when considering the choice between TGI and TJI joists for your construction project, it is important to carefully evaluate the specific requirements and considerations.

TGI joists are known for their strength, stability, and resistance to shrinking and warping, making them ideal for providing structural support. They offer excellent load-bearing capabilities, ensuring the durability and longevity of the building. However, they may come at a higher cost compared to TJI joists.

On the other hand, TJI joists are lightweight and can span further distances, allowing for larger open spaces or rooms. This makes them a cost-effective option, especially for projects with longer spans. However, it’s essential to ensure that TJI joists meet the required load and deflection ratios for your specific project.

To make the best decision for your project, it is recommended to consult with a structural engineer or a construction professional who can provide expert advice and help you assess the cost, strength, and span requirements. They will consider the load requirements, span distances, and budget considerations and guide you in selecting the most suitable option – be it TGI or TJI joists – to ensure the structural integrity and efficiency of your construction project.

FAQ

What is the difference between TGI and TJI joists?

TGI and TJI joists are both types of engineered wood joists. TGI joists are known for their strength, stability, and resistance to shrinking and warping, while TJI joists are lighter in weight and can span further distances.

What does TJI joist stand for?

TJI stands for Truss Joist I-Joist. It is a trademarked name for engineered wood I-joists.

What are TJI joists used for?

TJI joists are commonly used as interior floor joists, trusses, and headers in construction projects. They are designed to provide larger open spaces, span further distances, and allow for the passage of plumbing, electrical, and HVAC systems.

What sizes are available for TJI joists?

TJI joists are available in different widths and depths, ranging from TJI 110 to TJI 560. The specific size needed will depend on the requirements of the project and the desired span distance.

How far can TJI floor joists span?

The maximum span of TJI floor joists depends on various factors such as spacing between joists, load requirements, and design factors. The span can vary from 13’7″ for TJI 110 at 24″ centers to 36’1″ for TJI 560 at 12″ centers.

What are the differences between TGI and TJI joists?

Both TGI and TJI joists are engineered wood joists that offer benefits over traditional lumber. TGI joists are known for their strength, stability, and resistance to shrinking and warping. TJI joists, on the other hand, are lighter in weight and can span further distances.